Major Detail

Asset Publisher

- Prepare for a rewarding career in fast-growing industries.

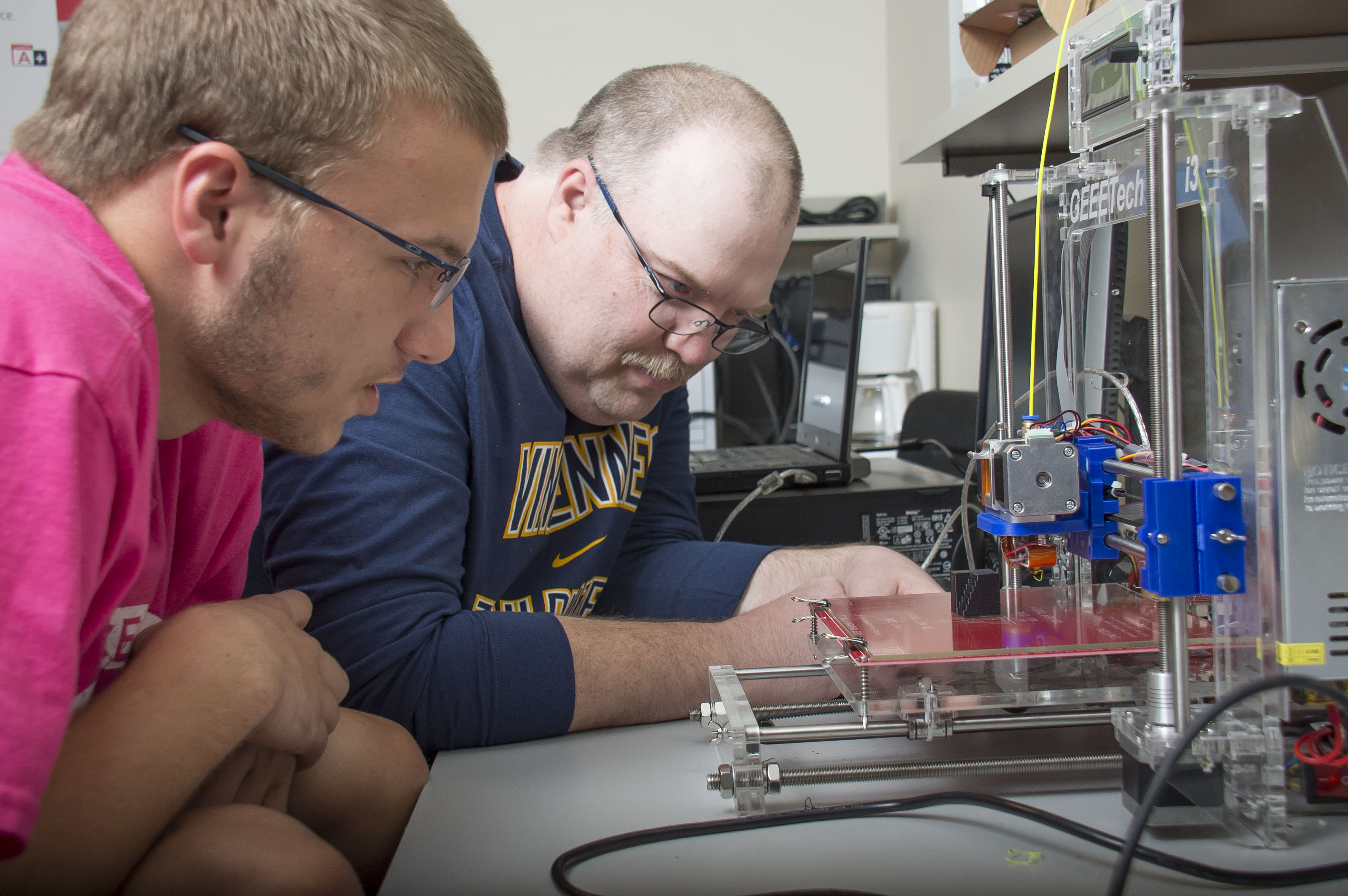

- Learn in a first-class facility that will give you hands-on experience using cutting-edge technology.

- The National Association of Manufacturers estimates that the United States could have more than 2 million unfilled manufacturing jobs by 2030.

Locations where this degree is offered:

Vincennes Campus

What can I expect during my time at VU?

- VU’s Advanced Manufacturing Technology program offers first-class training that prepares graduates to excel in fast-growing industries.

- The University’s instructors are true experts in their fields and readily available to help students gain the academic and practical skills they need to excel.

- The University offers substantial academic and social support systems to help students learn and grow.

- Small class sizes enable students to participate fully in activities and discussions and to seek out extra help when needed.

- Affordable tuition allows students to graduate with less debt.

Precision Machining is a highly skilled occupation in which raw material is machined and transformed into specialized industrial tooling.

Vincennes University offers the most comprehensive Precision Machining Technology program in Indiana, and is one of the few in the United States to offer specialized training in manual machining, CNC machining, metal stamping die, and plastic injection mold building.

With over 1,600 hours of hands on experience, students have the opportunity to develop a solid background in machine shop practices, as well as learn the set-up and operation for all basic types of manual and CNC machine tools. Classroom discussions focus on theory, terminology, and calculations.

The type and quality of equipment used in our labs include traditional machine tools as well as the latest in CNC equipment— identical to that found in industry. In addition, our faculty has an extensive background in education, teaching, and industry, to ensure that students receive instruction in both theory and practical applications.

Precision Machining Technology graduates have the option of applying for acceptance into our 14 week summer session, Advanced CNC Machining & Programming, providing them with an additional 500 hours of hands on CNC education, as well as a second Associates degree.

Starting salaries for VU’s Precision Machining graduates average in the $40,000 to $50,000 range with some far exceeding this. Job opportunities are excellent, with virtually 100 percent placement.

For more information, contact Scott Wallace, Program Coordinator, at 812-888-5521 or swallace@vinu.edu.

Precision Machining - Machinist Internship Program

Multiple vendors quote the VU PMTD tool list each calendar year. These quotes feature significant price savings and will be available to students during Start VU advising.

What can I do with this degree?

A degree from Vincennes University’s Advanced Manufacturing Technology program will prepare you for a lifelong career in an essential and growing profession.

Is this degree accredited?

Vincennes University's institutional accreditation from the Higher Learning Commission (HLC) and the specialized accreditations and approvals obtained by various programs are located on our Accreditation and Licensure page.

Vincennes University recognizes the importance of programmatic licensure, ensuring that graduates meet the requirements set by professional licensing boards. By adhering to rigorous standards and seeking recognition from accrediting bodies, Vincennes University demonstrates its dedication to offering quality education and preparing students for successful careers.

Have questions?

We are happy to chat with you to answer your questions and understand your personal goals.

Please reach out to us at VUADMIT@Vinu.edu or call 812-888-4313 for more information.